Polysense is an open-source fabrication process for creating smart textiles. It builds on traditional manual crafts and a DIY approach to allow the broadest audience to create novel smart textile sensors. Using this method, anyone can augment a plethora of fabric and textile samples to rapidly create sensors than can be worn on the body. It does not require specific equipment, except simple kitchen tools. The PolySense project was born in DataPaulette under the direction of Cedric Honnet. It continued at Saarland University with Paul Strohmeier and Marc Teyssier, during a series of research visits by Hannah Perner-Wilson (KobaKant) and Cedric. More information can be found at http://counterchemists.github.io/.

2020

Digital FabricationOpen Source

See also On-Body Sensors BodyStylus Markpad Eyecam Tactjam

New process makes fabric smarter

There are many ways of creating custom textiles, rooted in age-old traditions. For example, the colourful tie-dye motives of the sixties can be traced back to ancient Japanese shiburi. If you wish to create custom patterns, finding the tools and information to use them is easy.

Functional fabrics -- also known as smart fabrics or eTextiles -- have no such traditions. Instead one relies on expert knowledge or factory-produced materials. If lay-person wishes to create a custom functional fabric, most people would not know where to start.

With this project, we intend to make the creation of smart fabrics as accessible and easy to perform as creating a tie-dyed T-shirt.

How does it work?

PolySense uses a process called in-situ polymerization. This can be thought of as a dying process: one soaks a fabric in a chemical “dye” and when the fabric is removed from the fluid, it is electrically conductive.

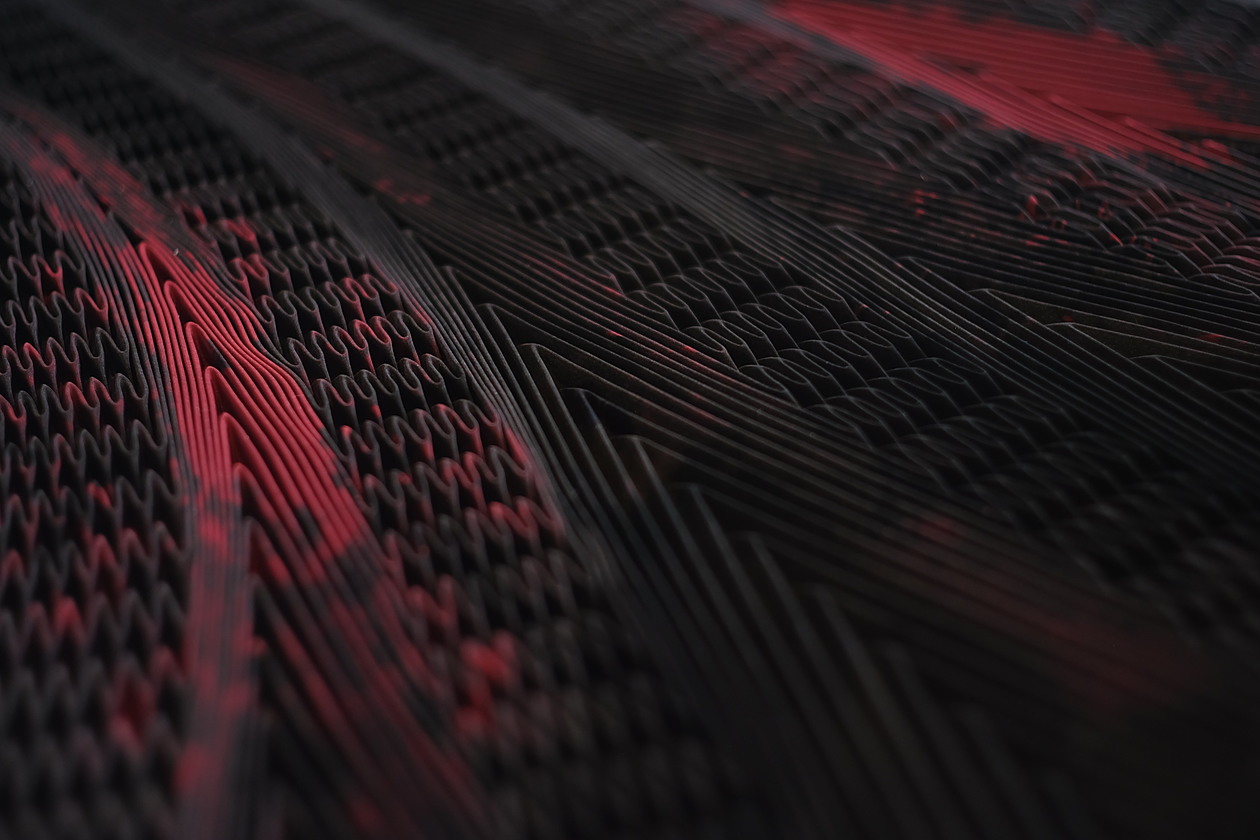

However, this is not a regular dye. During the dyeing process, a chemical reaction happens, after which each individual fibre of the textile is completely wrapped in chains of conductive polymer. This is called polymerization. "In-situ" means that the polymerization occurs within the fabric, at the place where one intends to use the resulting functional properties. This is radically different from existing DIY approaches, such as coatings, which apply a layer to the fabric, rather than the individual fibres, or literal stacking of fabric, where functional fabric is sewn or bonded on to non-functional materials.

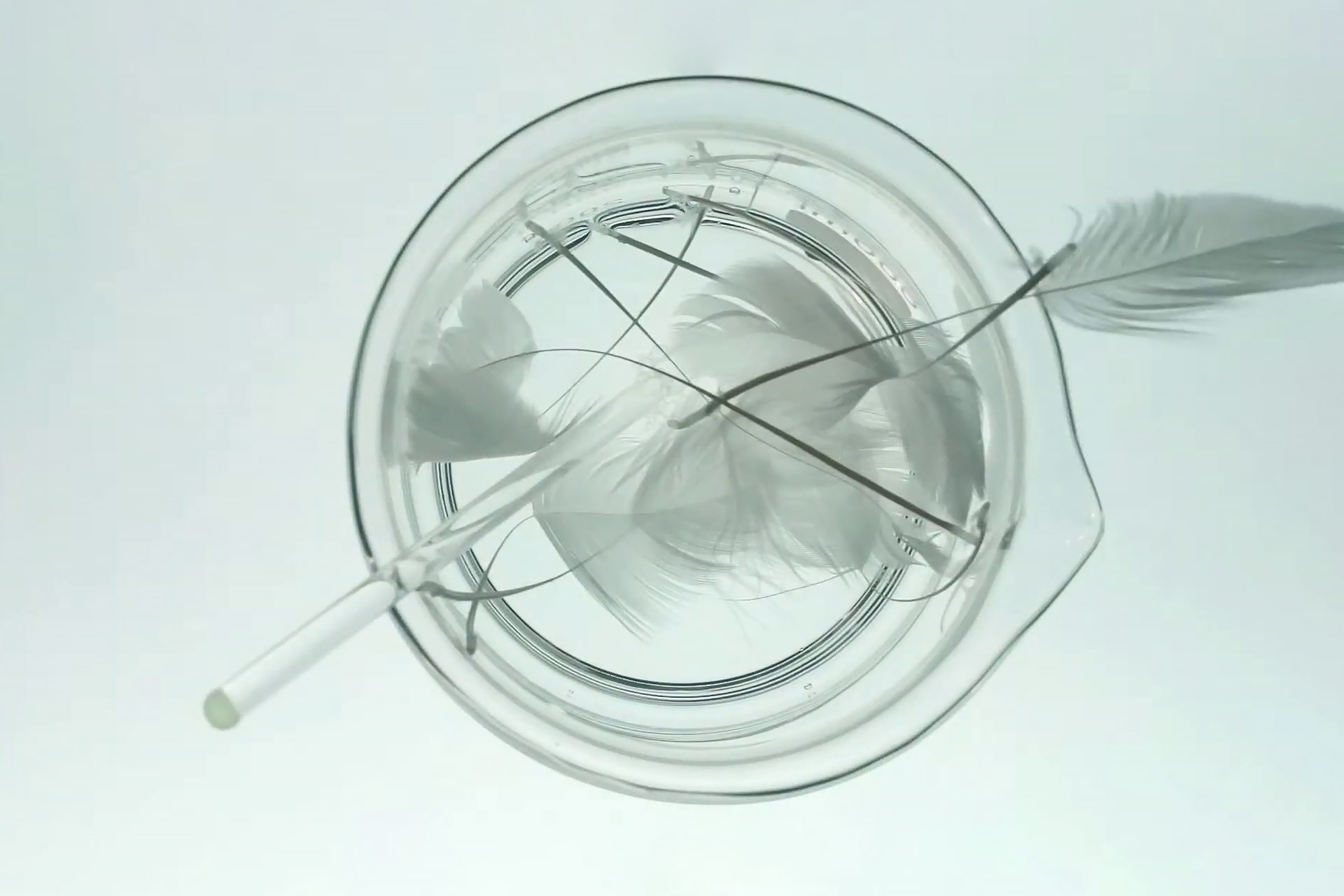

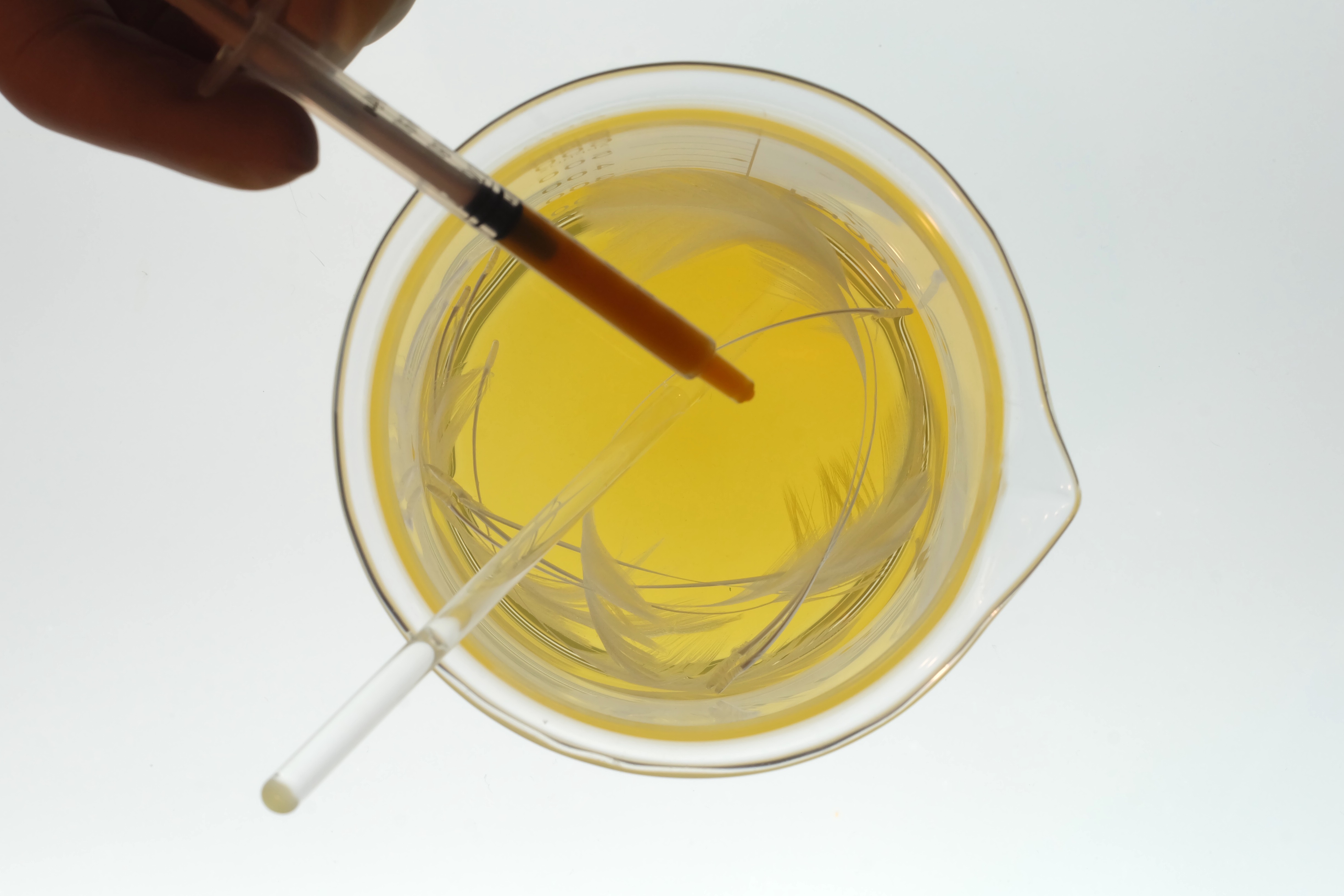

The process is easy to reproduce and can be completed in under an hour: First, the textile is soaked in a mix of water and Pyrrole for 10 minutes. Then the polymerization is initiated by adding Iron Chloride. Finally, the textile is stirred in this bath for about 30 minutes until polymerization is complete. This can be done in a small bowl, with a hand mixer, or in a washing machine, for larger quantities.

Project Stymphalian Birds by Audrey Briot using Polymerization process. Pictures credit to Audrey Briot.

Project Topographie Digitale by Audrey Briot. Pictures credit to Audrey Briot.

Polysense in the press

EurekAlert! - Saarland Informatics Campus - hackster.io

PolySense: Augmenting Textiles with Electrical Functionality using In-Situ Polymerization Cedric Honnet, Hannah Perner Wilson, Marc Teyssier, Bruno Fruchard, Jürgen Steimle, Ana C. Baptista, Paul Strohmeier CHI‘20: Proceedings of the ACM SIGCHI Conference on Human Factors in Computing Systems, pp.1-13